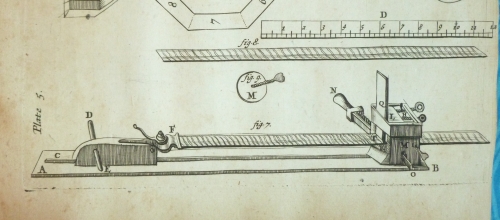

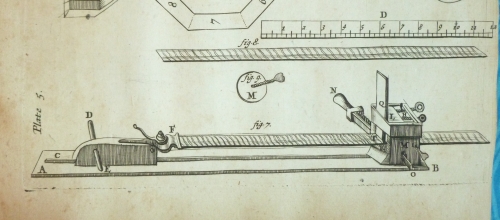

During my last visit to the Metropolitan Museum of Art I once again visited their exhibit on boxes and I was stuck once again by a ebony box with spectacular inlay. In addition all the panels and corners of the box are decorated with applied moldings and I thought here was a fine example of carved applied moldings that I could use along with more mundane examples. However as looked the piece over I realized that the molding wasn't carved. The regular designs were too perfect and didn't really have the depth and distinction you get with carving. I got hit with a lightbulb and I realized that the moldings were more probably done with a waving engine as described in Joseph Moxon's 1678 Mechanick Exercises. A belated reading of the caption to the piece confirmed my suspicion. The maker was Herman Doomer, Amsterdam c. 1640-50. Doomer son studied with Rembrandt and the master himself painted Doomer's portrait which is also at the During my last visit to the Metropolitan Museum of Art I once again visited their exhibit on boxes and I was stuck once again by a ebony box with spectacular inlay. In addition all the panels and corners of the box are decorated with applied moldings and I thought here was a fine example of carved applied moldings that I could use along with more mundane examples. However as looked the piece over I realized that the molding wasn't carved. The regular designs were too perfect and didn't really have the depth and distinction you get with carving. I got hit with a lightbulb and I realized that the moldings were more probably done with a waving engine as described in Joseph Moxon's 1678 Mechanick Exercises. A belated reading of the caption to the piece confirmed my suspicion. The maker was Herman Doomer, Amsterdam c. 1640-50. Doomer son studied with Rembrandt and the master himself painted Doomer's portrait which is also at the  met. You can see the portrait and learn more here. met. You can see the portrait and learn more here.

The piece is oak, veneered in ebony with ivory and mother-of-pearl inlay and without any additions it would still be quite magnificent, but the wave moldings give the carcass lots of additional interest which plain molding would not do.

It makes sense that Moxon who began his carrier in Holland was familiar with the machine because the machine originated in Holland. It makes sense that Moxon who began his carrier in Holland was familiar with the machine because the machine originated in Holland.

Essentially the machine is a fancy scratch beader. As you scrape the wood back and forth to produce the molding a ridged master pattern raises the cutter  and you get a wavy molding. Scratch beading works perfectly in brittle dense materials like ebony and ivory that you find in high end work. and you get a wavy molding. Scratch beading works perfectly in brittle dense materials like ebony and ivory that you find in high end work.

In the closeup photos, the best I could do through glass, you can see the moldings the machine produced. For a far more detailed and useful explanation of the history of the machine and how it works read Jonathan Thornton's excellent article here. Different versions of the machine would work vertical moldings as in this piece or with the addition of lateral motion you could make wiggly molding in both dimensions.

Hand powered machines like the engine were not uncommon in the pre-industrial age. They were used all over not so much to save labor - the machine worked by hand power, but to save skilled labor. And that's really important. It's important now for the same reason it was important 350 years ago. Considering the availability of machined parts the machine would be a lot easier to build now than then. If you want to make interesting pieces, especially if you are trying to make a living at it building a machine like this might be a simple way of creating tons of new effects that will wow your customers.

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

During my last visit to the

During my last visit to the  met. You can see the

met. You can see the  It makes sense that Moxon who began his carrier in Holland was familiar with the machine because the machine originated in Holland.

It makes sense that Moxon who began his carrier in Holland was familiar with the machine because the machine originated in Holland.  and you get a wavy molding. Scratch beading works perfectly in brittle dense materials like ebony and ivory that you find in high end work.

and you get a wavy molding. Scratch beading works perfectly in brittle dense materials like ebony and ivory that you find in high end work.

I've wanted to rebuild the chest to some extent at least, but wasn't sure about the molding. Now I have an idea how to do it.

So when is Tools for Working Wood going to offer one of these wavy machines?

Stephen

I've got to make one! 2014 is looking pretty clear.